Understanding the Basics of Laser Welding and Its Cost

Laser welding is a high-precision welding technique that uses a focused beam of light to melt and fuse two or more metals together. It is a popular choice in many industries due to its accuracy, efficiency, and cost-effectiveness. In this article, we will discuss the basics of laser welding and its cost.

Laser Welding Basics

Laser welding works by directing a high-powered laser beam onto the surface of the metal, causing it to melt and fuse together. The laser beam is controlled by a computer, which ensures precise and accurate welding. Laser welding can be used to weld various metals, including steel, aluminum, and copper.

There are two types of laser welding: conduction welding and keyhole welding. Conduction welding is used for thinner metals, where the laser beam heats the surface of the metal and melts it together. Keyhole welding, on the other hand, is used for thicker metals, where the laser beam creates a hole in the metal, allowing the laser energy to penetrate deeper into the metal, resulting in a stronger weld.

Laser Welding Machine Cost

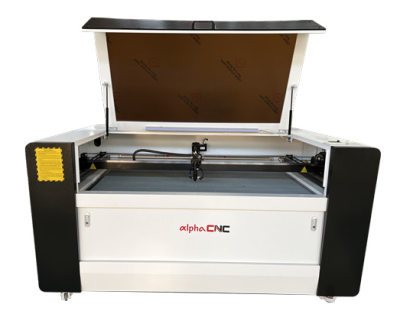

The cost of a laser welding machine can vary depending on various factors, including the type of machine, power output, and brand. The initial cost of a laser welding machine can range from a few thousand to tens of thousands of dollars.

However, it is important to consider the long-term cost savings of using a laser welding machine. Laser welding machines offer a high level of precision and control, resulting in less waste and rework. This reduces production time and costs, making it a cost-effective solution in the long run. Additionally, laser welding machines are energy-efficient and produce less heat, resulting in lower energy costs.

When considering the cost of a laser welding machine, it is also important to factor in maintenance and repair costs. Regular maintenance and proper use of the machine can extend its lifespan and reduce repair costs.

Conclusion

In conclusion, laser welding is a highly accurate and efficient welding technique that is widely used in various industries. The cost of a laser welding machine can vary depending on various factors, but the long-term cost savings and efficiency make it a cost-effective solution in the long run. Proper maintenance and use of the machine can further reduce repair costs and extend its lifespan. Understanding the basics of laser welding and its cost can help businesses make informed decisions about incorporating this technology into their manufacturing processes.